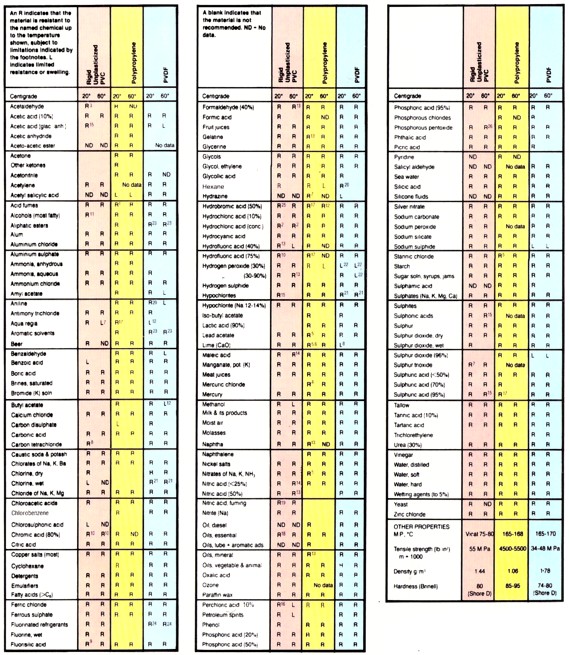

Listed below are the more commonly used materials of construction for processing plant and equipment and their resistance to named chemicals. Whilst every care is taken to ensure that the information given is accurate, it is only given as a general guide. Before users commit themselves to any material they are strongly advised to consult the relevant manufacturers or authorities about their application.

NOTES

Explanatory notes at lower temperatures may be taken to apply also at higher temperatures unless otherwise shown.

- Depending on the acid

- 35%

- Fair resistance

- Up to 40%

- Saturated solution

- Anhydrous

- Depending on concentration

- Discolouration and/or swelling and softening

- Up to 25%

- Up to 50%

- 5%

- May crack under stress conditions

- Depending upon composition

- Some attack at high temperature

- Some attack/absorption slow erosion

- 70%

- may cause stress cracking

- Depending on type

- 65%

- Some stress cracking at high pH

- PVDF special grade recommended for Solef Normal Kynar resistant

- Slight attack depends on grade

- PVDF not resistant to some of these

- Solef PVDF only resistant at Freon 113 and for below 75°c

- 20%

- Estimated effect

WE RESERVE THE RIGHT TO ALTER DETAILS OF OUR PRODUCTS AT ANY TIME WITHOUT PRIOR NOTICE.

All charts within this website are based on an air density of 1.2kg/m³